AI Apps

Transform Your Business with an AI-Powered Application

Our AIMESK AI Application Automates Repetitive Tasks

AI Apps

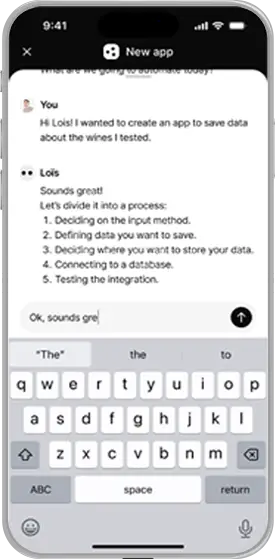

SmartAssistant.AI

AI Personal Assistant System

AI-Powered Assistant: A personal assistant integrated into your internal database, active 24/7. It is specifically trained for your business processes; it reminds tasks, queries data, prepares reports, and provides real-time analysis.

Custom Training for Business Processes It is specifically trained for your company and industry.

Database Integration: Seamlessly integrates with existing systems; provides real-time data access, reduces manual operations, and saves time.

24/7 Active Support: Provides uninterrupted and fast service at any time of the day.

Task Reminders: Provides timely notifications, ensuring no task is overlooked.

Reporting and Analysis: Prepares daily, weekly, and monthly reports on a scheduled basis. Analyzes data and delivers clear, actionable insights. Reports are automatically sent via email, WhatsApp, or AIMESK Messenger.

Secure Usage: All operations are carried out using structures that prioritize user and data security.

MES.AI

Production and Quality MES System

Detects anomalies in real time, analyzes production downtimes, and generates AI-based early warnings against quality deviations.

Real-Time Production Monitoring: Monitors all production processes in real time, allowing you to track machine, shift, and personnel performance from a centralized dashboard.

AI-Powered Efficiency Analysis: Analyzes production data, identifies bottlenecks, and enhances operational efficiency with AI-driven recommendations.

Automated Quality Inspection: Detects quality issues in products during production, classifies defects, and minimizes human error.

Adaptive Downtime Analysis System: A continuously evolving system powered by machine learning, it analyzes the causes of downtimes and provides insights to prevent their recurrence.

Instant Production Error Notification: Instantly alerts in case of issues on the production line, enabling rapid intervention and reducing potential losses.

Automated Reporting: Continuously monitors defined performance indicators and provides strategic insights to management through detailed reports and visualized charts.

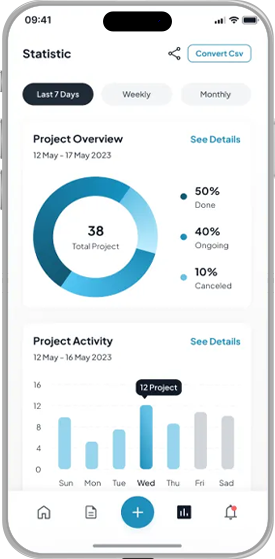

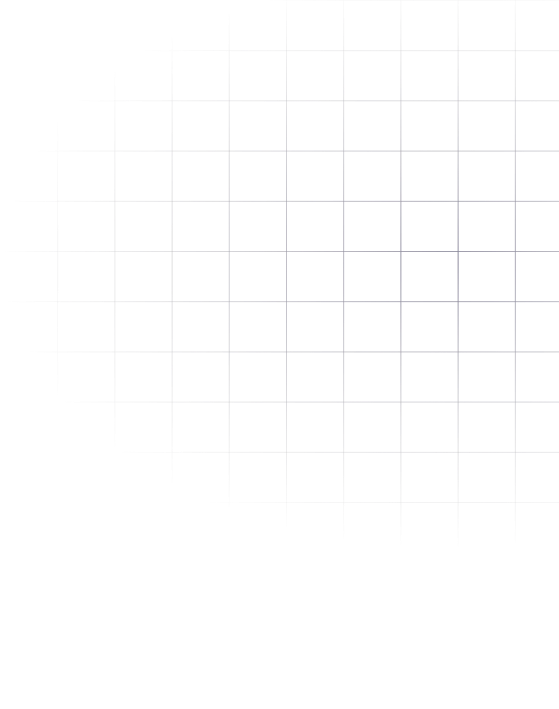

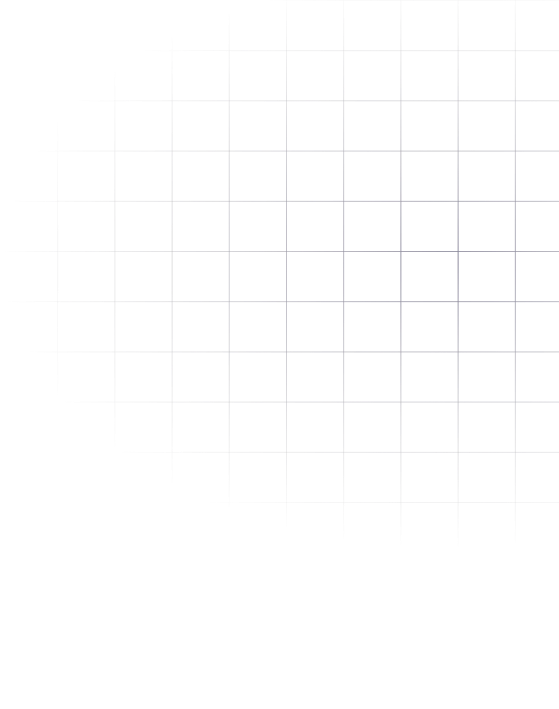

PYS.AI

Project Management System

Task Assignment & Progress Tracking: Easily manage assigned tasks, recurring activities, and the entire task history with minimal effort.

Smart Calendar Synchronization: All tasks are integrated with the calendar; conflicts are prevented and workload is balanced.

AI-Powered Time and Risk Estimation: The AI, learning from past projects, provides early warnings for delivery times and potential delays.

Delay Alert System: The AI analyzes task deviations and sends automatic notifications to those responsible.

Resource Planning and Budget Control: It provides detailed cost tracking and resource management for each project.

KPI Tracking and Automated Reporting: Real-time KPI tracking enables performance analysis; graphical and textual reports are provided to management.

Report Requests and Archive: Incoming report requests are managed from a single point, and historical data is securely archived.

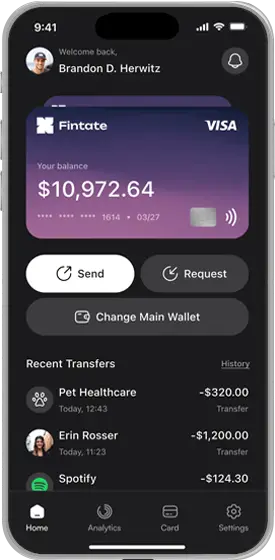

Finance.AI

Accounting & Finance System:

Automatic Classification of Card Expenses: It analyzes credit card transactions and automatically classifies expenses by category and location.

Out-of-Budget Expense Detection: It instantly detects transactions that exceed the established budget limits or are unauthorized, and provides alerts.

Spending Habit-Based Recommendations: It analyzes spending history based on users and departments, offering recommendations for savings and optimization.

Advanced Spending Dashboard: It enhances financial visibility with graphs and tables generated from real-time data.

Credit, DBS, and Collateral Tracking: Loans, promissory notes, letters of guarantee, and DBS transactions are monitored in an integrated manner through the system.

AI-Powered Currency Fixing and Risk Alerts: It monitors exchange rate movements, predicts the optimal times for currency fixing, and provides risk alerts in case of sudden changes.

Expense Type and Location-Based Analysis: It enables analysis of expenses based on their type (e.g., travel, procurement, personnel) and geographical location.

Automatic Cash Register Update: It automatically updates the digital cash balance by analyzing all cash inflows and outflows.

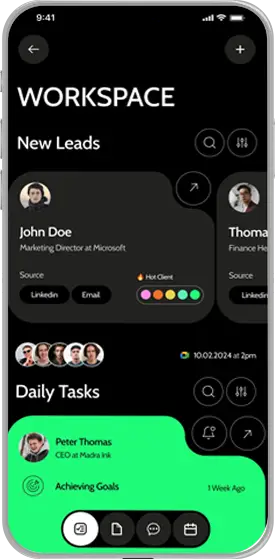

Sales.AI

CRM & Sales System

Sales Forecasting: It analyzes past sales data and generates weekly/monthly sales forecasts using AI algorithms.

Opportunity Scoring: It evaluates CRM data and assigns a conversion score to each potential customer; salespeople prioritize based on this score.

Quote to Sale Conversion Analysis: It analyzes conversion rates in the quote, proforma, and order processes to identify areas for improvement.

AI-Powered Customer Segmentation: It groups customers based on their types and recommends personalized sales strategies based on similar purchasing behaviors.

Sales Process Automation: Steps such as quote creation, status tracking, and invoice verification are automated with AI, reducing manual workload.

Call Center Integration: Trend analysis is conducted from call recordings, and recommendation systems are activated based on frequently asked topics and issues.

Warehouse & Shipment Compliance Check: It compares order and shipment data to detect delivery discrepancies early.

Invoice Compliance Analysis: It detects shipment-invoice discrepancies and provides alerts through the system.

LogiTrack.AI

License Plate Tracking & Logistics Management System:

Route Optimization and Delay Prediction: Using AI algorithms, it ensures vehicles follow the most efficient routes. By analyzing traffic, weather, and past delivery times, it predicts potential delays in advance.

License Plate-Based Vehicle Tracking: The shipment status of each vehicle is tracked using its license plate number. The location, departure time, and estimated arrival time of each vehicle are monitored in real-time.

Real-Time Shipment Tracking: All transportation processes are displayed live. Delivery stages are automatically updated through the system.

Shipment and Invoice Compliance Check: It checks whether the transportation and invoice details match; if there are discrepancies, the system provides an alert.

Logistics Performance Analysis: It analyzes metrics such as transportation time, delivery success, and vehicle efficiency to generate monthly logistics performance reports.

Warehouse & Shipment Integration: Warehouse exits are synchronized with transportation information. Missing or incorrect shipments are easily detected.

Catering.AI

Cafeteria Management System:

Meal Preparation Based on Shift Intensity: It automatically calculates the daily meal requirements based on personnel entry/exit and shift schedules, preventing overproduction or underproduction.

Smart Portion Estimation: It analyzes past consumption data to recommend the ideal portions per person, balancing both cost and inventory management.

Dynamic Menu Planning: It provides weekly/monthly menu plans based on seasonal ingredient availability, employee preferences, and health criteria.

Waste Prevention and Waste Tracking: It tracks the amount of uneaten food, analyzes the causes of waste, and provides sustainability recommendations.

Cafeteria Performance Reports: It regularly reports participation rates, meal quality feedback, and consumption statistics to management.

Stock and Material Consumption Integration: With integrated stock management in meal production, supply planning becomes more effective.

ServicePredict.AI

Technical Service & Predictive Maintenance System

Predictive Fault Analysis: It evaluates sensor data, usage duration, and historical maintenance records to identify equipment with a high likelihood of failure in advance.

Automatic Parts Replacement Scheduling: It tracks the lifespan of parts, automatically calculates when they need to be replaced, and integrates it into the maintenance plan.

Maintenance Calendar Suggestion: It suggests optimal maintenance times that do not conflict with production schedules, minimizing downtime.

Digitalization of Service Records: All technical service interventions are digitally recorded, and equipment history becomes accessible from a single panel.

Real-Time Fault Alerts: It detects unusual machine behaviors and sends real-time notifications to technical teams.

Maintenance Performance and Cost Reports: It provides detailed reports to management with analyses of maintenance activities, replaced parts, and downtime durations.

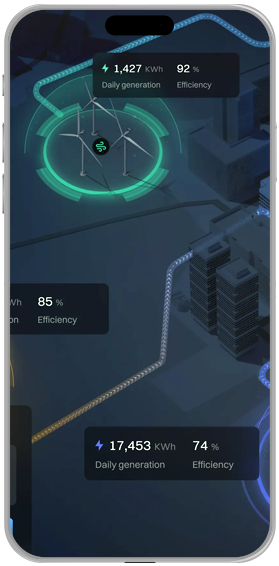

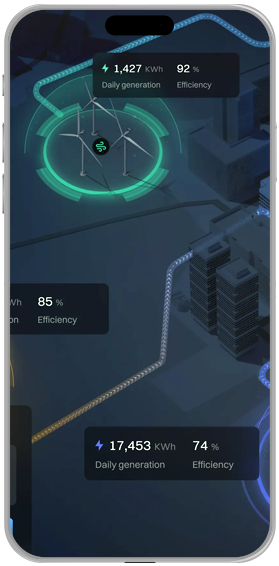

MachineWatch.AI

Machine Monitoring and Energy Analysis Dashboard

Real-Time Machine Performance Tracking: It tracks and records the production efficiency, cycle times, and downtime moments of machines in real-time.

Energy Consumption Analysis: The energy usage of each machine is monitored in detail; equipment with excessive consumption is identified.

Visualization of Efficiency Losses: Lost time, low speed, and inefficiencies caused by breakdowns are reported graphically, supported by indicators such as OEE (Overall Equipment Efficiency).

AI-Powered Performance Comparison: It compares machines on the same production line with each other, detecting any non-standard performances.

Automatic Anomaly Alerts: It sends automatic notifications to the technical team in case of unusual energy consumption, sudden stoppages, or unexpected performance declines.

Time-Based Production Data: It reports production and energy statistics based on shifts, days, weeks, and months, offering comparative analysis with historical data.

InsightBoard.AI

Dashboard & Strategic Intelligence Panel

Cross-Module Data Correlation: It establishes cause-and-effect relationships between different systems such as production, maintenance, sales, energy, and finance; for example, revealing the connection between energy consumption and fault frequency.

AI-Powered Insight Generation: The system analyzes large datasets to provide managers with suggestions on unpredictable trends, risks, and opportunities.

Advanced Time Series Analysis: It detects patterns between date-based data, analyzes the source of seasonal changes, and provides data-driven support for operational strategy.

Master Filter and Dynamic Data Filtering: Filtering can be done based on parameters such as date, location, production line, and staff group; each user can personalize their own dashboard.

Interactive Graph and Table Visualizations: Data is presented through tools such as graphs, heat maps, and pivot tables. Detailed analysis is enabled through the visualizations.

Anomaly Detection and Alert System: It detects abnormal data behaviors (such as sudden drops, excessive increases, etc.) and notifies managers about points that need to be analyzed.

HRAccess.AI

Human Resources Smart Timekeeping and Access Control Management System

Access Control & Shift Tracking: It automatically tracks employee attendance by analyzing card, RFID, or biometric access data.

Smart Timekeeping Generation: It analyzes shift compliance, overtime, tardiness, and absence data with AI, generating accurate and complete timekeeping records.

Payroll Integration: The system, integrated with HR parameters, directly initiates payroll calculation and reporting processes from timekeeping data.

Absence and Leave Reports: It classifies all absence reasons such as tardiness, sick leave, and unpaid leave, and automatically sends them to HR.

Real-Time Tracking with HR Dashboard: Employee movements, production-shift relations, payroll statistics, and HR KPIs can be monitored live.

End-to-End Process Integration from Employee Applications to Performance: Starting from job applications, the employee list, performance tracking, payroll, and leave processes are seamlessly interconnected.

SmartStock.AI

Raw Material Tracking System & RFID-based Inventory Management System

RFID-Supported Material Movement Tracking: The movement of raw materials to the production area, warehouse, or intermediate points is automatically recorded through RFID gates.

AI-Based Stock Consumption Forecasting: Stock depletion timelines are predicted based on historical consumption data, and the system provides alerts when necessary.

Incorrect Material Flow Detection: Stocks that are moved to the wrong location or incorrectly directed are instantly analyzed and reported.

Automatic Matching of Production Inflows and Outflows: Raw material inputs are matched with production line consumption to verify production accuracy.

Full Integration with ERP and Production Modules: It works fully compatible with systems such as Logo, SAP, and Netsis; it is also directly linked to production orders.

NeuralVision.AI

Visual Processing Management Dashboard

Real-Time Camera Stream and Defect Display: All camera footage from the production line is viewed live on the panel. The AI instantly detects defects and highlights the error points, presenting them visually to the operator. No errors are ever overlooked.

AI Model Status and Performance Monitoring: Metrics such as model accuracy, processing speed, last training date, and detection success can be monitored in real-time. The impact of evolving models is measured through graphs.

Defect Archive: Date, Category, and Visual Records: Each detected defect is archived in the system with a timestamp, class label, and camera image. Retrospective quality analyses can be easily conducted.

Operator Activity and Intervention Statistics: It reports in detail when each operator intervened, how quickly they responded to specific errors, and all human-machine interactions. This data serves as a foundation for training and auditing.

Model Update Option Based on Quality Criteria: The AI model can be retrained based on new product groups, changing quality tolerances, or production revisions. Evolving processes are accompanied by evolving algorithms.